Non-Rising Stem Gate Valve Top 10 for Efficient Flow Control

2025-12-30

In the world of industrial flow control, precision and reliability are paramount. Among the many valve types available, non-rising stem gate valves stand out for their efficiency and durability—ideal for applications where space and performance matter. But with so many options on the market, how do you choose the best? In this blog, we’ll dive into the top 10 non-rising stem gate valves that excel in efficient flow control, helping you make informed decisions for your systems. At DRIFCO, we understand the critical role these valves play, and we’re here to guide you through the standout products that can enhance your operations. Stay tuned as we explore the features, benefits, and innovations that set these valves apart—let’s unlock smoother, more reliable flow together.

Understanding the Basics of Non-Rising Stem Gate Valves

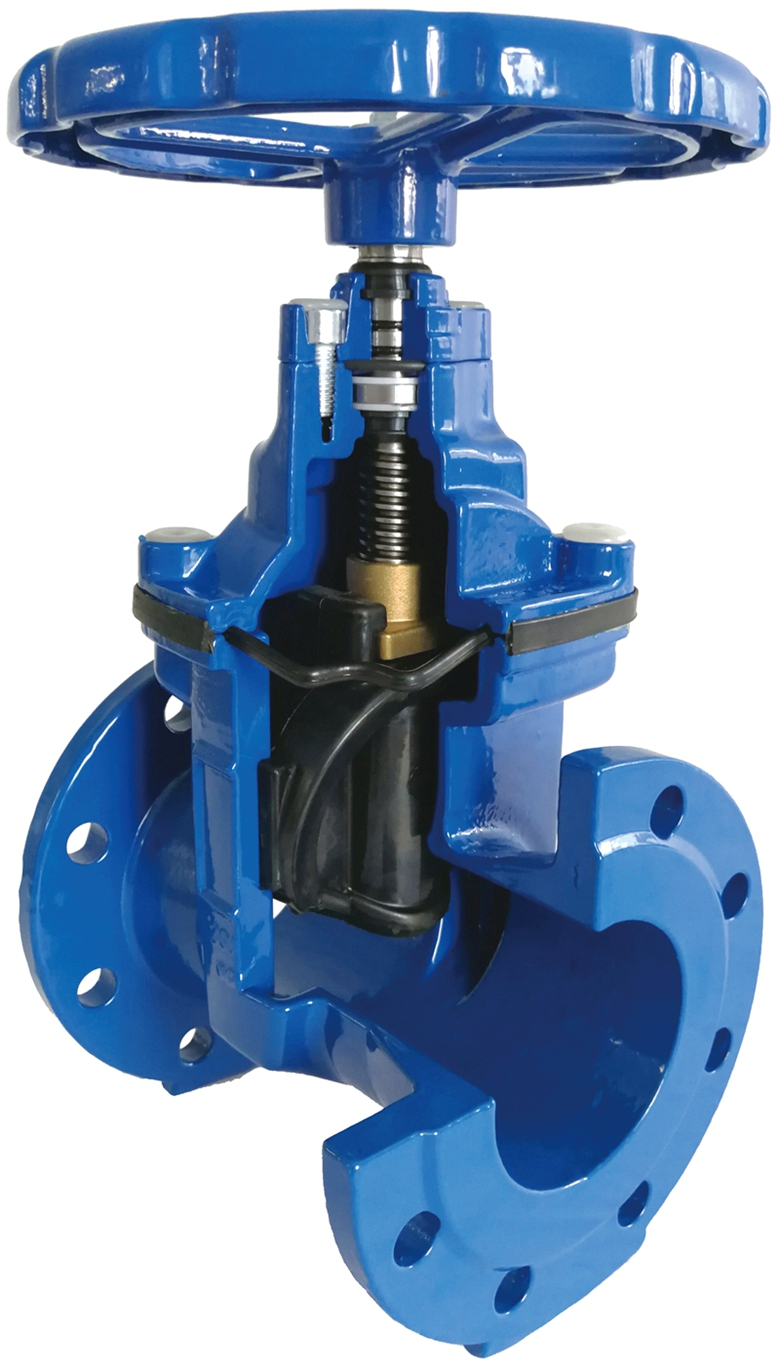

Non-rising stem gate valves, often referred to as NRS valves, feature a design where the stem does not protrude upward during operation. Instead, the stem threads into the gate, causing it to move vertically without changing the valve's overall height. This makes them ideal for applications with limited vertical space, such as underground installations or tight piping systems where clearance is a concern. Unlike rising stem valves, NRS types require less maintenance on the stem threads since they are protected inside the valve body, but they can be harder to visually inspect for position indication.

A key advantage of non-rising stem gate valves is their compactness, which allows for installation in confined areas without sacrificing functionality. The internal threading mechanism ensures smooth gate movement, reducing wear and tear over time. However, this design can pose challenges for maintenance; since the stem doesn't rise, it's more difficult to detect stem corrosion or damage without disassembly. Common uses include water distribution networks, industrial pipelines, and fire protection systems, where space efficiency and reliability are prioritized.

In practice, selecting a non-rising stem gate valve often depends on specific environmental factors. For instance, in corrosive or high-temperature settings, materials like stainless steel or bronze are chosen to enhance durability. The valve's operational mechanism, involving a handwheel or actuator that rotates the stem to lift the gate, ensures a tight seal when closed, preventing leaks. While they might not offer the visual feedback of rising stem valves, NRS variants excel in applications demanding minimal footprint and consistent performance, making them a staple in modern piping infrastructure where space and efficiency are key considerations.

Key Features that Enhance Flow Control Efficiency

Optimizing flow control isn't just about tweaking valves; it's about integrating smart technologies that anticipate and adapt to system demands in real time. By leveraging predictive analytics and dynamic adjustments, flow control systems can minimize energy waste and prevent costly disruptions. This proactive approach ensures smooth operations even under fluctuating conditions, making processes more resilient and efficient.

Another game-changer is the use of advanced materials and compact designs that reduce pressure drops and maintenance needs. These innovations allow for more precise control with less physical footprint, which is especially beneficial in space-constrained environments. Imagine a system that not only performs better but also lasts longer with fewer interventions—this is what modern flow control solutions deliver, setting them apart from older, bulkier alternatives.

Finally, seamless integration with digital platforms and IoT devices transforms flow control from a standalone function into a connected component of a larger ecosystem. This connectivity enables remote monitoring and automated responses, empowering teams to manage systems from anywhere. It's this blend of reliability, adaptability, and connectivity that truly enhances flow control efficiency, turning routine operations into strategic advantages.

Top 10 Materials for Durability and Corrosion Resistance

When selecting materials that excel in durability and corrosion resistance, engineers and designers often turn to a select group of high-performance options. These materials are chosen not just for their ability to withstand harsh environments, but also for their long-term reliability, reducing maintenance costs and extending product lifespans. From industrial applications to everyday consumer products, the right material can make all the difference in performance and safety.

Among the top contenders, stainless steel stands out for its versatility and resistance to rust, thanks to chromium content that forms a protective layer. Titanium, though lightweight, offers exceptional strength and immunity to many corrosive agents, making it ideal for aerospace and medical implants. In marine settings, materials like Monel and Inconel are prized for their ability to fend off saltwater corrosion, while ceramics and certain polymers provide excellent chemical resistance in aggressive industrial processes.

Beyond these, advanced composites and coatings are pushing boundaries, offering tailored solutions for specific challenges. For instance, fiber-reinforced polymers combine durability with corrosion resistance in infrastructure projects, while specialized alloys like Hastelloy handle extreme temperatures and acidic environments. Understanding the unique properties of each material helps in making informed choices, ensuring optimal performance and sustainability across various sectors.

Installation Tips to Maximize Valve Performance

Getting your valves installed just right can really make them perform better and last longer. Start by clearing out the pipe area to prevent any gunk or debris from getting stuck inside, which could mess with how well the valve works. Make sure everything lines up perfectly to avoid putting extra strain on the parts, and don't forget to double-check the connections for any leaks right away.

One thing people often overlook is letting the valve adjust to the temperature of its surroundings before putting it in place. This simple step helps stop warping or stress cracks from forming. Also, pick the right gaskets and seals for your setup; going with materials that match your system's needs can keep things running smoothly and cut down on maintenance down the line.

After you've got everything in place, give it a thorough test with the actual conditions it'll face, like pressure changes or flow rates. This real-world check can catch small issues early on. Keep a close eye on how it's doing at first and tweak anything as needed to make sure it delivers top-notch performance from the get-go.

Maintenance Best Practices for Long-Term Reliability

Proactive maintenance isn't just a checklist—it's a mindset shift. By integrating predictive analytics and condition monitoring, you can spot potential issues before they escalate, reducing unexpected downtime and extending asset lifespan. This approach moves beyond reactive fixes, fostering a culture of continuous improvement where data drives decisions, ultimately enhancing reliability and operational efficiency. It’s about staying ahead of the curve, not just responding to it.

Clear documentation is the backbone of any successful maintenance strategy. Detailed records of inspections, repairs, and part replacements create a valuable history that helps future teams understand equipment behavior and performance trends. This transparency enables better planning and resource allocation, ensuring consistency across shifts and personnel. Well-kept logs not only boost accountability but also streamline training and knowledge transfer, preventing repeat issues and building a robust reliability framework over time.

Regular training and skill development are crucial for long-term reliability. Equip your team with the latest techniques and tools through hands-on workshops and refresher courses, empowering them to handle complex systems confidently. This investment in human capital enhances problem-solving abilities and adaptability, leading to more effective maintenance practices. When staff feel competent and engaged, they're more likely to take ownership, fostering a proactive environment that supports sustained reliability goals.

Applications in Industrial and Commercial Settings

In industrial and commercial environments, robotics and automation technologies have moved beyond basic assembly lines to streamline complex processes, enhancing both speed and consistency. From manufacturing plants to logistics centers, these systems tackle repetitive tasks with precision, reducing human error and operational costs. For instance, automated guided vehicles (AGVs) seamlessly navigate warehouses, handling material transport while freeing up staff for more strategic roles, directly boosting productivity and safety.

Beyond logistics, smart sensors and IoT devices are revolutionizing facility management by optimizing energy use and maintenance schedules in commercial buildings. In retail, automated inventory systems track stock in real-time, preventing shortages and overstocking, which improves customer satisfaction and reduces waste. This integration of data-driven solutions allows businesses to make quicker, more informed decisions, fostering agility in competitive markets without relying on generic, one-size-fits-all approaches.

In sectors like agriculture and construction, specialized robotics are tackling labor-intensive challenges, such as precision planting or 3D printing structures, showcasing versatility beyond traditional settings. By adapting to unique industry demands, these applications highlight how tailored automation can drive innovation, making operations not just efficient but also more sustainable and resilient in the face of evolving global trends.

FAQ

A non-rising stem gate valve keeps the stem's exterior position fixed during operation, making it ideal for tight spaces where vertical clearance is limited, as the gate moves internally without rising above the valve body.

The top 10 models feature precision-engineered gates and bodies that minimize flow resistance, allowing smooth, unrestricted passage of fluids while maintaining reliable shut-off capabilities under varying pressures.

These valves are often made from durable materials like stainless steel, carbon steel, and bronze to withstand corrosion, high temperatures, and abrasive media, ensuring longevity in harsh environments.

They excel in applications such as underground piping, confined compartments in ships, and HVAC systems, where space constraints require a compact design without sacrificing performance.

Regular lubrication of the stem threads and periodic inspection for wear or leaks are key, as the internal mechanism can accumulate debris over time, potentially affecting operation if neglected.

Designed with robust sealing mechanisms and sturdy construction, they provide excellent pressure containment and leak-proof performance, often outperforming ball or butterfly valves in demanding high-pressure scenarios.

Conclusion

The selection of a non-rising stem gate valve is crucial for efficient flow control, balancing durability and performance in demanding environments. Understanding the basics of these valves, which feature a stem that does not extend outward during operation, is key to their compact design and reliability. Key features enhancing flow control efficiency include full-port flow paths, tight sealing mechanisms, and smooth operation that minimizes pressure drop. For long-term effectiveness, the top 10 materials—such as stainless steel, brass, and specialized alloys—offer exceptional corrosion resistance and strength, ensuring the valve withstands harsh industrial conditions without compromising functionality.

Proper installation tips, like aligning the valve correctly and ensuring adequate support, maximize performance and prevent leaks. Maintenance best practices, such as regular lubrication and inspection of seals, promote long-term reliability and reduce downtime. Applications in industrial and commercial settings range from water treatment plants to HVAC systems, where these valves provide precise control in pipelines. By integrating these aspects, users can achieve optimal flow management, making non-rising stem gate valves a superior choice for efficient and reliable operations in various sectors.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com