Bronze Bonded Grinding Wheels: Shaping the Future of Precision Machining

2023-10-17

Introduction

In the world of manufacturing and metalworking, precision and efficiency are paramount. Whether you're creating intricate components for aerospace or crafting high-quality tools for various industries, the tools you use can make all the difference. One such indispensable tool is the bronze bonded grinding wheel. These wheels have revolutionized the grinding and machining processes, delivering exceptional precision, durability, and versatility. In this blog, we'll delve into the fascinating world of bronze bonded grinding wheels, exploring their composition, applications, and their role in shaping the future of precision machining.

Understanding Bronze Bonded Grinding Wheels

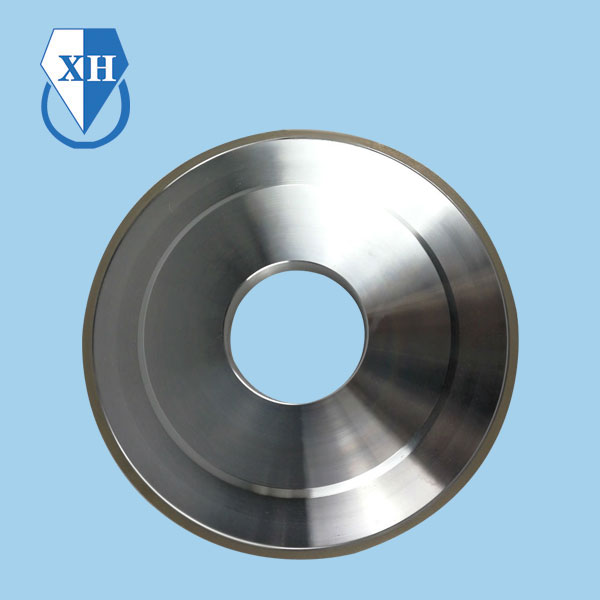

Bronze bonded grinding wheels are abrasive tools used for grinding, shaping, and finishing various materials, including metals, ceramics, and composites. What sets them apart is the bonding agent used in their construction. While traditional grinding wheels often use resin, vitrified, or metal bonds, bronze bonded wheels incorporate bronze, a copper alloy, as the bonding material. This unique composition offers several advantages that make them stand out in the machining industry.

Key Features of Bronze Bonded Grinding Wheels

1. Bronze Bonding Agent: Bronze's exceptional properties, including high tensile strength and heat resistance, make it an ideal bonding agent for grinding wheels. It ensures secure attachment of abrasive particles while withstanding the heat generated during the grinding process.

2. Versatility: Bronze bonded grinding wheels are compatible with a wide range of abrasive materials, including diamond, cubic boron nitride (CBN), and various aluminum oxides, enabling them to tackle diverse machining tasks.

3. Precision and Control: These wheels offer exceptional precision and control during material removal, resulting in finely finished surfaces and intricate shapes.

4. Durability: The robust composition of bronze bonding makes these wheels highly durable, reducing the frequency of wheel replacements and overall machining costs.

5. Cooling Properties: Bronze bonded wheels dissipate heat effectively, reducing the risk of thermal damage to the workpiece and prolonging the wheel's life.

Applications of Bronze Bonded Grinding Wheels

1. Metalworking: Bronze bonded grinding wheels are commonly used for precision grinding, shaping, and sharpening metal components, such as cutting tools, gears, and bearings.

2. Aerospace: In the aerospace industry, these wheels are indispensable for machining high-strength materials like titanium, stainless steel, and superalloys used in aircraft and spacecraft components.

3. Automotive: Bronze bonded grinding wheels play a crucial role in the manufacturing of automotive parts, including engine components, brake rotors, and transmission gears.

4. Tool Manufacturing: Manufacturers of cutting tools and drills rely on these wheels for precise tool geometry and sharpness.

5. Ceramics and Composites: Bronze bonded grinding wheels are effective in shaping and finishing ceramic and composite materials used in advanced manufacturing processes.

6. Precision Machining: In industries where precision is paramount, such as medical device manufacturing and optical lens production, bronze bonded wheels ensure the highest level of accuracy.

The Future of Precision Machining

As technology continues to advance and industries demand ever-higher levels of precision and efficiency, bronze bonded grinding wheels are likely to play an even more significant role in shaping the future of machining. With their versatility, durability, and ability to work with advanced abrasive materials like CBN and diamond, these wheels will remain a cornerstone of precision manufacturing. Their contribution to the production of high-quality components across various sectors is undeniable, and their evolution promises to unlock new possibilities in the world of precision machining.